產品詳情

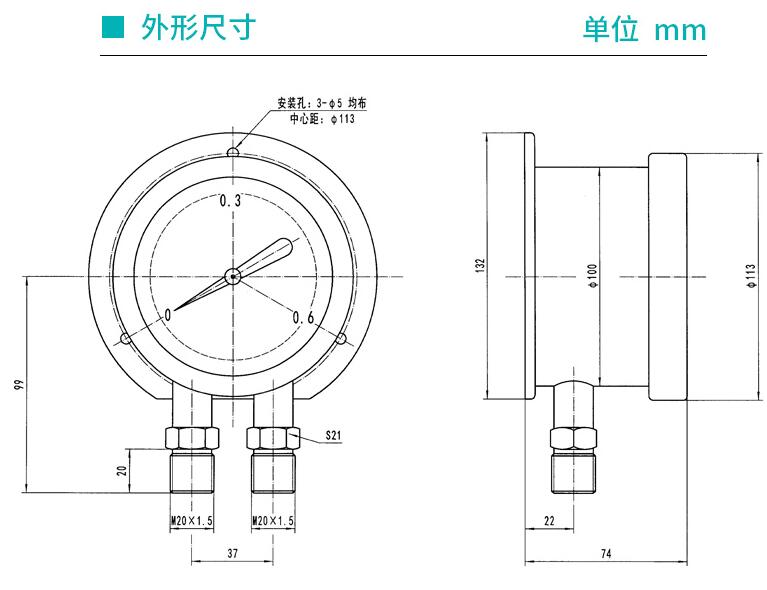

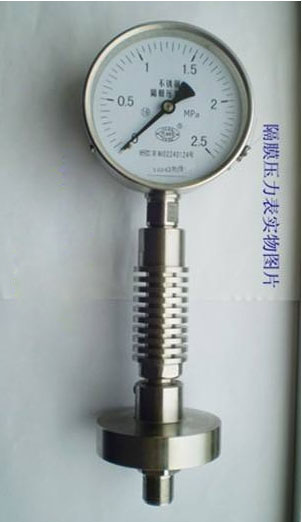

CYW-152B及CYW-153B不銹鋼差壓表(以下簡稱差壓表 )適用于化工、化纖、冶金、電力、核電等工業部門的工藝流程中測量各種液(氣)體介質的差壓、流量等參數。不銹鋼差壓表結構全部采用不銹鋼制成,其中的測量系統(雙波紋管及連接部件)、導壓系統(包括接頭、導管等)采用特種奧氏體不銹鋼制成,具有較強的耐腐蝕及抗工作環境侵蝕影響。儀表整體結構設計合理、工藝先金、具有體積小、重量輕、穩定性好、使用壽命長、外觀新穎、適應性強等優點。儀表接頭的連接形式有平行式(可直接與三閥組連接)和斜式兩種,能夠適應不同用戶的配套安裝。 BJZ壓(ya)力變送(song)(song)器(qi)_�������差(cha)壓(ya)變送(song)(song)器(qi)_液位變送(song)(song)������器(qi)_溫(wen)度變送(song)(song)器(qi)

■ CYW-152B及CYW-153B不銹鋼差壓表結構原理:

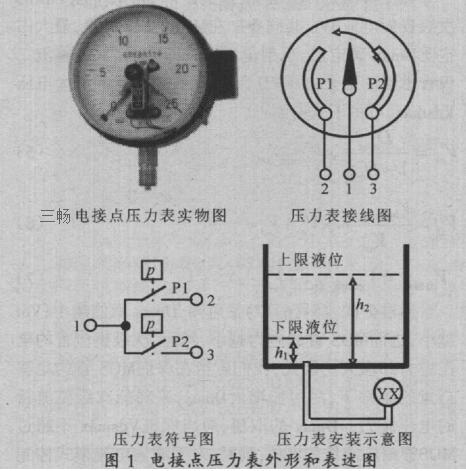

儀表采用雙波紋管結構,即兩只波紋管分別安裝在“工”字型支架兩側的對稱位置上。“工”字型支架的上下兩端分別為活動端和固定端,中間由彈簧片相連接;兩只波紋管呈平行狀態,分別用導管與表殼上的高低壓接頭相連接;齒輪傳動機構直接安裝在支架的固定端,并通過拉桿與支架的活動端相連接;度盤則直接固定在齒輪傳動機構上。

儀表的工作原理:基于感壓元件采用兩只具有相同剛度的波紋管,因此在同一被測介質下迫使其產生相同的集中力分別作用于活動支架上,由于彈簧片兩側在等力矩作用下不產生擾度,故支架還處于原始位置,這樣齒輪傳動機構也不動作,使指針仍指在零位。

當施加不同壓力(一般高壓端高于低壓端)時,兩波紋管作用在活動支架上的力則不相等,使分別產生相應的位移,并帶動齒輪傳動機構傳動并予放大,由指針偏轉后指示出兩者之間的差壓值。

友情提(ti)示:因為(wei)不銹鋼差壓(ya)(ya)表的(de)差壓(�����ya)(ya)顯示不能低于滿量程的(de)1/6,故(gu)量程范(fan)圍選擇時需要考(kao)慮#大應(ying)用壓(ya)(ya)力。如有(you)其他要求,須我廠技術確認并澄清后可定制(zhi)。

■ CYW-152B及CYW-153B不銹鋼差壓表主要技術指標:

1.差壓的測量范圍、公稱工作壓力、***度等級及接頭螺紋尺寸:BJZ壓力變(bian)送(song)(song)器(qi)_差(cha)壓變(bian)送(song)(song)器(qi������)_液位變(bian)送(song)(song)器(qi)_溫度(du)變(bian)送(song)(song)器(qi)

BJZ壓(ya)力變������(bian)送器(qi)_差壓(ya)變(bian)送器(qi)_液位變(bian)送器(qi)_溫度變(bian)送器(qi)

|

差壓的測量范圍BJZ壓(ya)力變送(song)(song)器_差壓(ya)變送(song)(song)������器_液位變送(song)(������song)器_溫(wen)度變送(song)(song)器

|

公稱工作壓力BJZ壓(ya)(ya)力變送(song)器_差壓(ya)(ya)變送(s��������ong)器_液位變送(song)器_溫度變送(song)器

|

***度等級BJZ壓(ya)力(li)變送(song)器_差壓(ya)變送(������song)器_液位變送(song)器_溫(wen)度變送(song)器

|

頭螺紋尺寸BJZ壓力變(bian)(bian)送器_差壓變(bian������)(bian)送器_液位變(bian)(bian)送器_溫度變(bian)(bian)送器

|

|

0~10 0~16 0~25

0~40 0~60 0~100BJZ壓(ya)力變送器(qi)(qi)_差壓(ya)變送器(qi)(qi)_液位變送器(qi)(qi)_溫度變送����器(qi)(qi)

|

KPaBJZ壓力變(bian)送(song)器(qi)(q�����i)_差壓變(bian)送(song)器(qi)(qi)_液位(wei)變(bian)送(song)器(qi)(qi������)_溫度變(bian)送(song)器(qi)(qi)

|

60 100 160

250 400 600BJZ壓(ya)力(li)變(bian)送器_差(cha)壓(ya)變(bian)������送器_液位變(bian)送器_溫度變(bian)送器

|

BJZ壓力變送(song)(son������g)器_差(cha�������)壓變送(song)(song)器_液位變送(song)(song)器_溫度變送(song)(song)器

KPaBJZ壓力變送器_差壓變送器_液位變送器_溫度變送器

|

2.5BJZ壓(ya)力(li)變(bian)送器(qi)_差壓(ya)變(bia��������n)送器(qi)_液位變(bian)送器(qi)_溫(wen)度變(bian)送器(qi)

|

M20x1.5

NPT 1/2BJZ壓力變(bian)(bian)送(song)器(qi)_差(cha)壓變(bian�������)(bian)送(song)器(qi)_液位變(bian)(bian)送(song)器(����qi)_溫(wen)度變(bian)(bian)送(song)器(qi)

|

|

0~0.16 0~0.25 0~0.4

0~0.6 0~1 0~1.6

0~2.5�������BJZ壓力變送(song)器_差壓變送(song)器_液(ye)位變送(song)器_溫度(du)變送(song)器

|

MPaBJZ壓(ya)力變(bian)(bian)送器(qi)(qi)_差壓(ya)變(bian)(bian)送器(qi)(qi)_液(ye)位(wei)變(bian)(bian)送器�����(qi)(qi)_溫(wen�������)度變(bian)(bian)送器(qi)(qi)

|

1 1.6 2.5

4 6 10 10BJZ壓力變(bian)(bian)送(song)器_差(cha)壓變(bian)(bian)送(song)器_液位(wei)變(bian)(bian)送(son�������g)器_溫度變(bi������an)(bian)送(song)器

|

MPaBJZ壓力變送(song)器(qi)_差壓變�������送(song)器(qi)_液位������變送(song)器(qi)_溫度(du)變送(song)器(qi)

|

2.導壓系統及外殼等材質:BJZ壓力變送器(qi)(qi)_差壓變送器(qi)(qi)_液位變送器(qi)(qi���������)_溫度變送器(qi)(qi)

BJZ壓力變(bian)送(song)器_差(cha)壓變(bian)送(song)器_液(ye)位變(bian)送(song)器_溫度變(bian)送(s�����ong)器

|

零件名稱BJZ壓力變(bian)送器(qi)(qi)_差壓變(bian)送器(qi)(qi)_液(ye)位變(bian)送器(qi)(qi)_溫度變(������bian)送器(qi)(qi)

|

材質牌號(代號)BJZ壓力變送(song)(song)�������器(qi)_差�����壓變送(song)(song)器(qi)_液位變送(song)(song)器(qi)_溫(wen)度變送(song)(song)器(qi)

|

|

接頭、導管BJZ壓力變送器(qi)_差壓變送器(qi)_液位變送器(qi)_溫度變送器(qi)

|

0Cr17Ni12Mo2(316)BJZ壓力(li)變送器_差壓變送器_液(ye)位變送器_溫度(du)變送器

|

|

波紋管BJZ������壓力變(bian)送(song)器_差�����壓變(bian)送(song)器_液位變(bian)送(song)器_溫度變(bian)送(song)器

|

00Cr17Ni14Mo2(316L)BJZ壓力變送器_差壓變送器_液位變送器_溫度變送器

|

|

表殼、表蓋、表環BJZ壓(ya������)力變(bian)送器(qi)_差壓(ya)變(bian)送器(qi)_液(ye)位變����(bian)送器(qi)_溫度變(bian)送器(qi)

|

0Cr18Ni9(304)BJZ壓力變送器(qi)_差壓變送器(qi)_液位變送器(qi)_溫度變送器(qi)

|

3.使用環境溫度:-40~70℃

4.重量:約1.5kg

5.儀表外殼防護等級:IP54

6.儀表技術性能符合企業標準Q/YXBM831-1997《 不銹鋼差壓表 》

7.抗工作環境振動:V.H.3級

訂(ding)貨需知:型號/表(biao)盤直徑/材質/安裝方式/壓力范圍/接頭螺紋/#大靜壓

安全警告(gao):為(wei)安全起(qi)見(jian),請選(xuan)擇正確型號的(�������de)(de)產品(pin)(pin),如(ru)若產品(pin)(pin)的(de)(de)選(xuan)擇或者使(shi)用(yong)不當(dang),將可能會導(dao)致財產的(de)(de)損失或者人身的(de)(de)傷(shang)害,系(xi)統的(de)(de)設計者及用(yong)戶應當(dang)完(wan)全負責選(xuan)擇正確的(de)(de)產品(pin)(pin)和按照正確的(de)(de)方(fang)法使(shi)用(yong)產品(pin)(pin)

關注我們 實現共贏

關注我們 實現共贏