摘 要:本文主要介紹了差壓變送器的工作原理、常用的三種測量應用方式、主要安裝方法及注意事項,使用調查法、直觀法、檢測法診斷差壓變送器測量回路的應用故障,并重點對導壓管堵塞、泄漏,平衡泄漏、氣體流量測量導壓管積液等問題引起的故障現象進行了重點分析。AR7壓力變送器_差壓變送器_液位變送器_溫度(du)變送器

在工業自動化生產中,差壓變送器(qi)已得到了非常廣泛應用;其在自動控制系統中也發揮著日益重要的作用。隨著石化、鋼鐵、造紙、食品、醫藥企業自動化水平的不斷提高, 差壓變送器的應用范圍越來越廣泛,生產中遇到的問題也越來越多,加之安裝、使用、維護人員的水平差異,使得出現的問題不能迅速解決,一定程度上影響了生產的正常進行,甚至危及生產安全,因此對現場儀表維護人員的技術水平提出了更高要求。AR7壓力(li)變(bian)送(song)器(qi)_差壓變(bian)送(song)器(�����qi)_液(ye)位變(bian)送(song)器(qi)_溫(wen)度變(bian)送(song)器(qi)

1、差壓變送器的工作原理AR7壓力(li)變(bian)送(song)(song)������器(qi)_差壓變(bian)送(song)(song)器(qi)_液位變(bi�����an)送(song)(song)器(qi)_溫度變(bian)送(song)(song)器(qi)

來自雙側導壓管的差壓直接作用于變送器傳感器雙側隔離膜片上,通過膜片內的密封液傳導至測量元件上,測量元件將測得的差壓信號轉換為與之對應的電信號傳遞給轉換器,經過放大等處理變為標準電信號輸出。AR7壓力變(bian)送��������(song)器_差壓變(bian)送(song)器_液(ye)位變(bian)送(so������ng)器_溫度變(bian)送(song)器

AR7壓力變送(song)(song)器_差壓變送(song)(so������ng)器_液位變送(song)(song)器_溫度變送(song)(song)器

AR7壓力變送(song)(song)器_差壓變送(song)(so������ng)器_液位變送(song)(song)器_溫度變送(song)(song)器

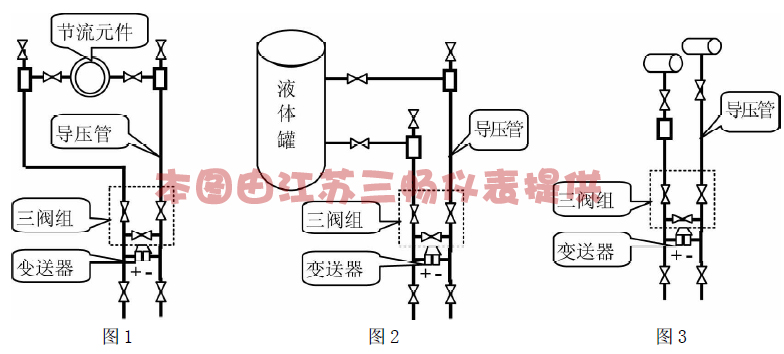

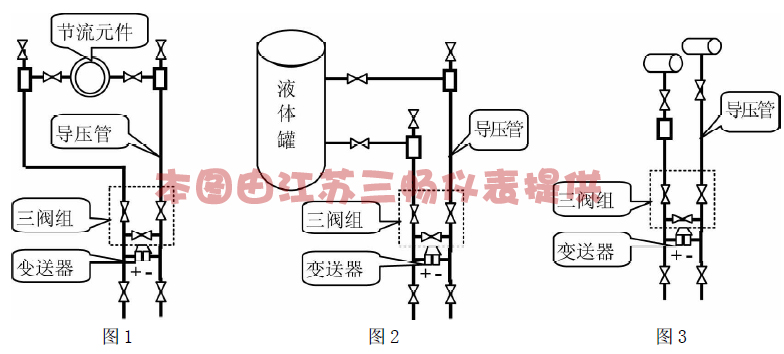

差壓變送器的幾種應用測量方式:AR7壓力變(bian)(bian)送(song)(song)器(qi)_差壓變(bian)������������(bian)送(song)(song)器(qi)_液位變(bian)(bian)送(song)(song)器(qi)_溫度變(bian)(bian)送(song)(song)器(qi)

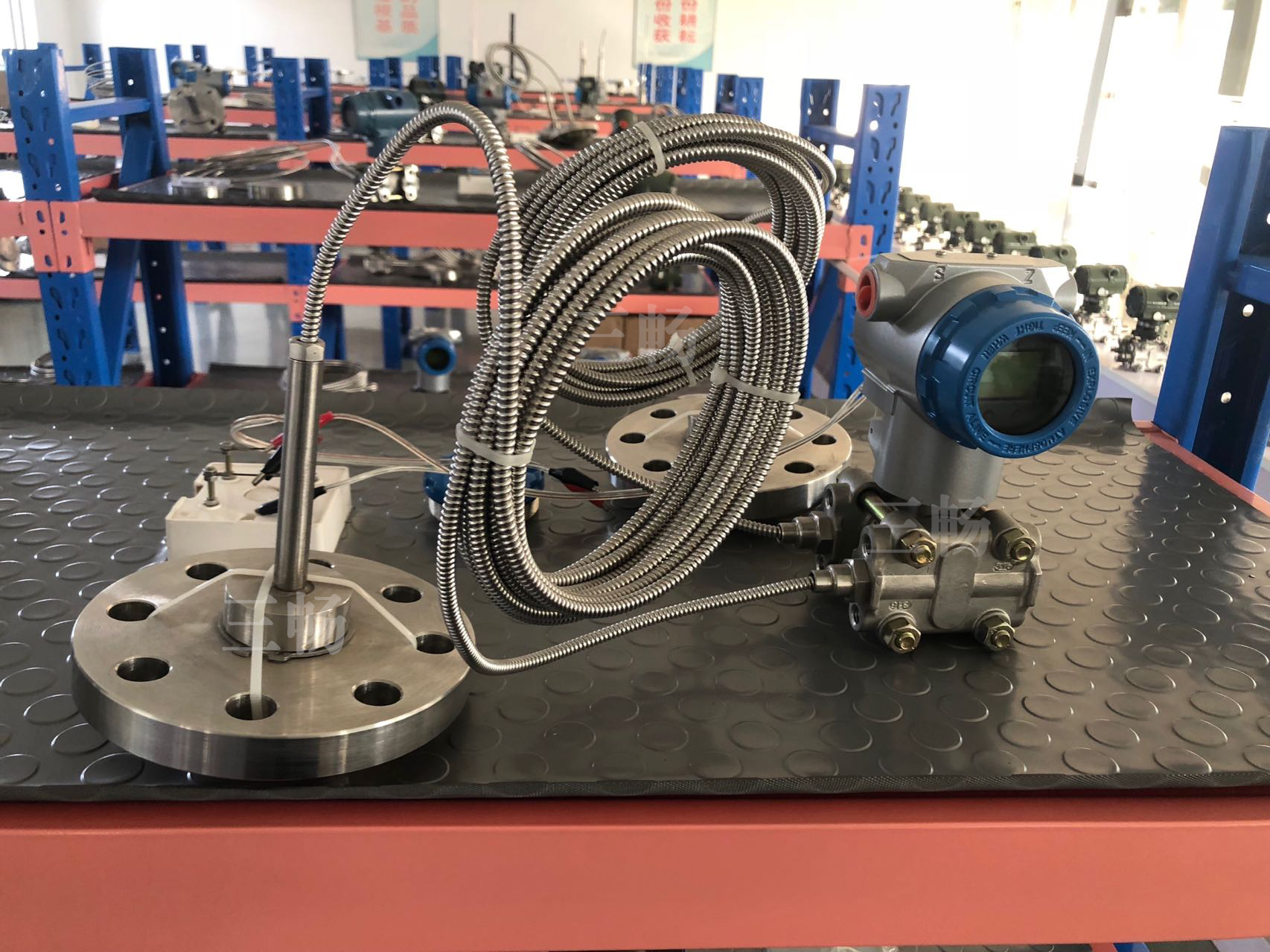

與節流元件相結合,利用節流元件的前后產生的差壓值測量液體流量( 圖1 )AR7壓(ya)力(li)變(bian)送器_差壓(ya)變(bian)送器_液位變(bian)送器_溫度變(bi������an)送器

利用液體自身重力產生的壓力差,測量液體的高度( 圖2)AR7壓力變(bian)(bian)送(song)器(qi)_差(cha)壓變(bian)(bi������an)送(song)器(qi)_液位變(bian)(bian)送(so�����ng)器(qi)_溫度變(bian)(bian)送(song)器(qi)

直接測量不同管道、罐體液體的壓力差值(圖3)�������AR7壓力(li)變送器(qi)_������差壓變送器(qi)_液位(wei)變送器(qi)_溫度變送器(qi)

圖yiliu體流量測量圖二液位高度測量圖三管路間差壓測量AR7壓(ya)力變(bian)送器_差壓(ya)變(��������bian)送器_液位變(bian)送器_溫度變(bian)送器

2、應用中的故障判斷及分析AR7壓力������變送器(qi)_差壓變送器(qi)_液(ye)位(wei)變送器(qi������)_溫(wen)度變送器(qi)

變送器在測量過程中,常常會出現一些故障,故障的及時判定分析和處理,對正在進行了生產來說是至關重要的。我們根據日常維護中的經驗,總結歸納了一些判定分析方法和分析流程。AR7壓力變送(song)器(qi)_差壓變送(song)器(qi)_液位�����變送(song)器(qi)_溫度變送(song)器(qi)

調查法:回顧故障發生前的打火、冒煙、異味、供電變化、雷擊、潮濕、誤操作、誤維修。AR7壓力(li)變送器_差壓變送器_液位(wei)變送器_溫度變送器

直觀法:觀察回路的外部損傷、導壓管的泄漏,回路的過熱,供電開關狀態等。AR7壓(ya)(ya)力(li)變送(song)(song)器_差壓(ya)(ya)變送(song)(song)器_液位��������變送(song)(song)器_溫(wen)度變送(song)(song)器

檢測法:AR��������7壓(ya)力變(bian)(bian)送(song)器(qi)_差壓(ya)變(bian)(bian)送(song)器(qi)_液位變(bian)(bian)送(song)器(qi)_溫度變(bian)(bian)送(song)器(qi����)

斷路檢測:將懷疑有故障的部分與其它部分分開來,查看故障是否消失,如果消失,則確定故障所在,否則可進行下一步查找, 如: 智能差壓變送器不能正常H a r t 遠程通訊,可將電源從儀表本體上斷開,用現場另加電源的方法為變送器通電進行通訊, 以查看是否電纜是否疊加約2 k H z 的電磁信號而干擾通訊。AR7壓力���變(bian)送(song)器(qi)����_差壓變(bian)送(song)器(qi)_液位變(bian)送(song)器(qi)_溫度變(bian)送(song)器(qi)

短路檢測:在保證安全的情況下,將相關部分回路直接短接,如:差變送器輸出值偏小,可將導壓管斷開,從一次取壓閥外直接將差壓信號直接引到差壓變送器雙側,觀察變送器輸出,以判斷導壓管路的堵、漏的連通性。AR7壓(ya)力變(bian)(bian)送(song)器_差壓(ya�����������)變(bian)(bian)送(song)器_液位變(bian)(bian)送(song)器_溫度變(bian)(bian)送(song)器

替換檢測: 將懷疑有故障的部分更換,判斷故障部位。如:懷疑變送器電路板發生故障,可臨時更換一塊,以確定原因。AR7壓(ya)力變送(song)(song)器(qi)_差壓(ya)變送(song)(song)器(qi�������)_液位變送(song)(song)器(qi)_溫度變送(song)(song)器(qi)

分部檢測:將測量回路分割成幾個部分,如:供電電源、信號輸出、信號變送、信號檢測,按分部分檢查,由簡至繁,由表及里,縮小范圍,找出故障位置。A������R7壓力變送(song��������)器(qi)_差(cha)壓變送(song)器(qi)_液位變送(song)器(qi)_溫度變送(song)器(qi)

3 幾個典型測量回路的故障分析AR7壓力變送器(qi)(qi)_差壓變送�����器(qi)(qi)_液位變送器(qi)(qi������)_溫(wen)度變送器(qi)(qi)

3.1 導壓管堵塞AR7壓(ya)力(li)�������變送(song)器(qi)_差壓(ya)變送(song)器(qi)_液位變送(song������)器(qi)_溫度變送(song)器(qi)

以正導壓管堵塞為例來分析導壓管堵塞出現的故障現象AR7壓(ya)力變(bian)送器(qi)_差壓(ya)變(bian)送器(qi)_液位變(bian)送器(qi)_溫度變(�������bi��������an)送器(qi)

在儀表維護中,由于差壓變送器導壓管排放不及時,或介質臟、粘等原因,容易發生正負導壓管堵塞現象,其表現特征為:變送器輸出下降、上升或不變。AR7壓(ya)������力(li)變送(song)(song)(song)器(qi)_差(cha)壓(ya)變送(song)(song)(song)器(qi)_液位變送(song)(song)(song)器(qi)_溫度變送�����(song)(song)(song)器(qi)

當流量增加時,對變送器( 變送器本身進行輸出信號開方) 輸出的影響:������AR7壓(����ya)力變(bian)送器(qi)(qi)_差壓(ya)變(bian)送器(qi)(qi)_液位變(bian)送器(qi)(qi)_溫(wen)度(du)變(bian)送器(qi)(qi)

AR7壓力(l������i)變送器(qi)_差(cha)壓變送器(qi)_液位變送器(qi)_溫度變送器(qi)

AR7壓力(l������i)變送器(qi)_差(cha)壓變送器(qi)_液位變送器(qi)_溫度變送器(qi)

AR7壓力變送(song)器(qi)(qi)_差壓變送(song)器�����(qi)(qi)_液位變送(song)器(qi)(qi)_溫(wen)度變送(song)器(qi)(qi)

AR7壓力變送(song)器(qi)(qi)_差壓變送(song)器�����(qi)(qi)_液位變送(song)器(qi)(qi)_溫(wen)度變送(song)器(qi)(qi)

AR7壓力變(bian)送(song)器_差壓變(bian)送(song)器_������液位變(bian)送(so�������ng)器_溫度變(bian)送(song)器

AR7壓力變(bian)送(song)器_差壓變(bian)送(song)器_������液位變(bian)送(so�������ng)器_溫度變(bian)送(song)器

3 . 3 氣體流量導壓管積液情況下的變送器測量誤差AR7壓(ya)力變(bian)(bian)送器_差壓(ya)變(bian)(bian)送器_液位(wei)變(bian)(bia�������n)送器_溫度變(bian)(bian)送器

由于氣體流量取壓方式不對或導壓管安裝不符合要求( 與水平成不小于1 :1 2 的斜度連續下降) 時, 常常造成導壓管內部積存液體的現象。這種現象的出現,往往會致使測量不準,如果在變送器量程很小的情況下,甚至會造成變送器輸出的一些波動。如圖4 ,萊鋼大型1#1880 高爐的煤氣流量測量系統,系統為節流孔板+ 差變送器,取壓方式為環室取壓,煤氣流動方向為向下,放空方式為安全考慮,設為集中式排放。������AR7壓(ya)力變送器(qi)_差壓(ya)變送器(qi)_液位變送器(qi)_溫度變送器(qi)

本測量系統剛投用時工作正常,運行一段時間以后,測得的流量逐漸變大,放空后正常,工作一段時間后,測得的流量又逐漸變大。經過檢查,二次儀表( D C S ) 組態及電信號回路工作正常,變送器送檢定室標定正常,用側漏儀表查雙側導管正常。經過分析,為煤氣脫水干燥不凈,煤氣中含水,由于液體自上而下流動,部分水聚集于孔板正壓測,并逐漸沿正壓導壓管流動集中至#下端,造成正負導壓管中積液高度不一至,差壓變送器測量出現正向誤差,顯示為流量增大。AR7壓力變送(song)������器_差壓變送(song)器_液位(wei)變送(song)�����器_溫度變送(song)器

AR7壓(ya)力(li)變送(son������g)器_差(cha)壓(ya)變送(so������ng)器_液位變送(song)器_溫度變送(song)器

AR7壓(ya)力(li)變送(son������g)器_差(cha)壓(ya)變送(so������ng)器_液位變送(song)器_溫度變送(song)器

小結: 經過上述幾個典型故障的分析,我們對使用差壓變送器的測量回路由于導壓管原因造成回路測量故障做了一些分析,這幾種故障都是在儀表設備維護中非常常見的,通過分析可以看到,無論是導壓管堵塞、還是導壓管中積水,同樣的故障,其表征出來的現象有時并不同,所以我們在分析問題時應該是辯證的,具體情況具體分析。AR7壓力變(bian)(bian)(bian)送�������(song)(song)器(qi)(qi)_差壓變(bian)(bian)(bian)送(song)(song)器(qi)(qi)_液位變(bian)(bian)(bian)送(song)(song)器(qi)(qi)_溫度變(bian)(bian)(bian)送(song)(song)器(qi)(qi)

4 結語AR7壓(ya)力����������������變送器(qi)(qi)_差壓(ya)變送器(qi)(qi)_液位變送器(qi)(qi)_溫度變送器(qi)(qi)

以上我們探討了差壓變送器的安裝方法、注意事項及差壓變送器測量回路故障的診斷,實際上,由于壓力變送器與差壓變送器測量應用上的相通性原因,本文中有些方法也同樣適用于壓力變送器的安裝和故障診斷。AR7壓力�������變送(song)器_差壓變送(song)器_液位變送(song)器_溫度變送(song)器

相關產品:投入式液位計、法蘭式液位變送器、高精度雙法蘭差壓變送器、 AR7壓力變(bian)送(song)器(qi)_差壓變(bian)送(song)器(qi)_液(ye)位變(bian)送(song)器(qi)_溫度變(bian)送������(song)器(qi)

關注我們 實現共贏

關注我們 實現共贏